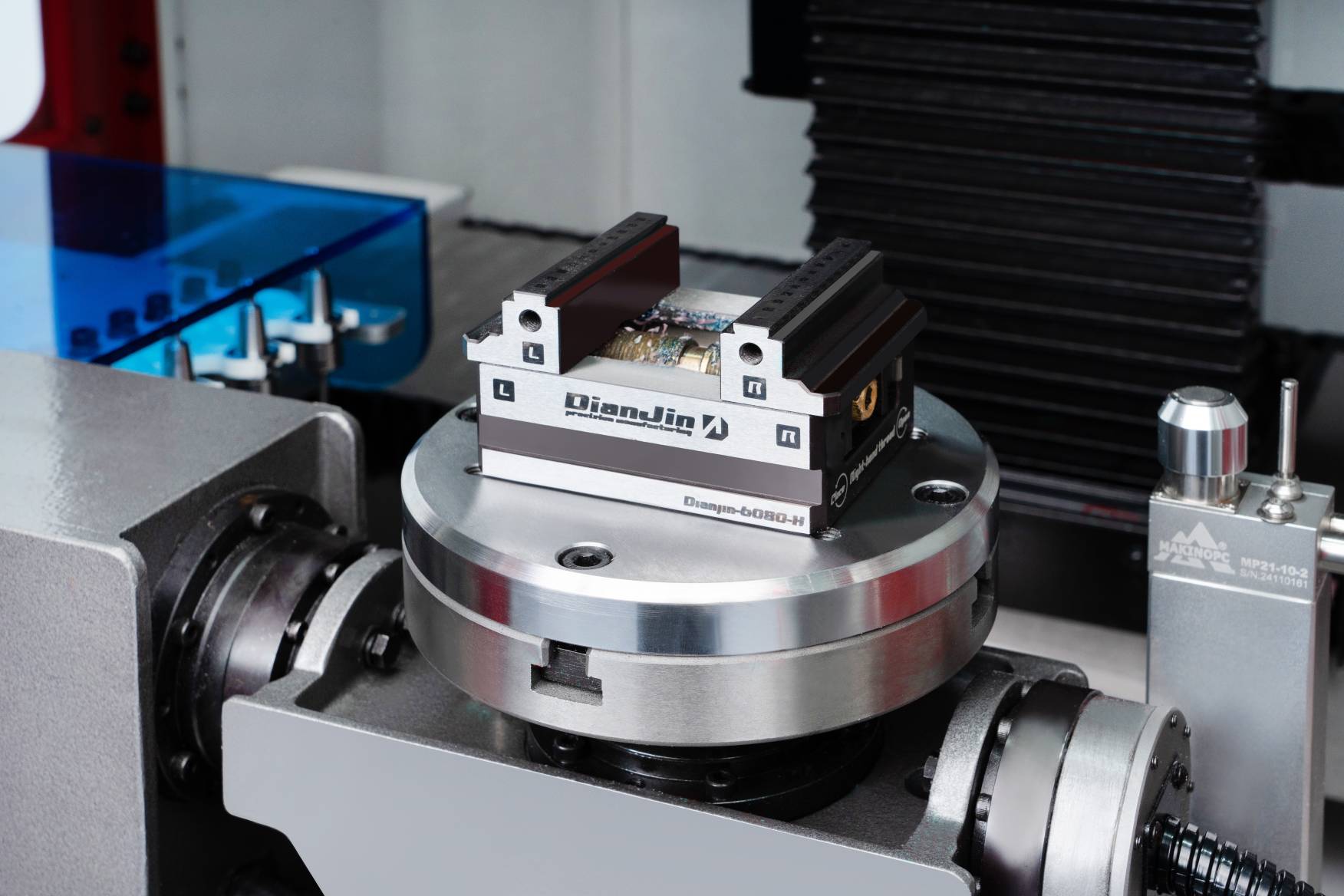

ECO1-Pro 5-axis Milling Machine

•Integrated rigid cast bed with Ac structure;

•Adopting high speed electric spindle;

•Adopting high quality ball screw and guide rail;

•Using own developed SIEG 5-axis system, with high cost-effectiveness;

•Multiple functions such as RTCP / tool length compensation / coordinate system offset / inclined surface machining;

| Table | Table size | φ130 mm |

| Max load | 10 kg | |

| Travel | X travel | 300 mm |

| Y travel | 320 mm | |

| Z travel | 300 mm | |

| A swing angle | -90°~+120° | |

| C swing angle | 360° | |

| Working area | φ100x120 mm | |

| Spindle | Spindle taper | T11 |

| Spindle speed | 40000 r/min | |

| Spindle power | 2.2 Kw | |

| Axis | X/Y/Z speed | 5 m/min |

| A swing speed | 20 rpm | |

| C swing speed | 20 rpm | |

| X/Y/Z motor | 3 Nm | |

| A/C motor | 2.2 Nm | |

| Tool magazine | Tool number | 4 |

| Max. tool diameter | 7 mm | |

| Max. tool length | 60 mm | |

| Max. tool weight | 0.2 kg | |

| Accuracy | X/Y/Z positioning accuracy | 0.015 mm |

| A/C positioning accuracy | 30 sec | |

| X/Y/Z repeatability accuracy | 0.01 mm | |

| A/C repeatability accuracy | 20 sec | |

| Others | Pneumatic supply | 0.6 Mpa |

| Power | 3.5 KVA | |

| Machine weight | 520 kg | |

| Overall dimension | 1600x960x2000 mm | |

| Packaging size | 1710x1310x2220 mm |

.png?x-oss-process=image/resize)

.png?x-oss-process=image/resize)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.jpeg?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)